Homepage

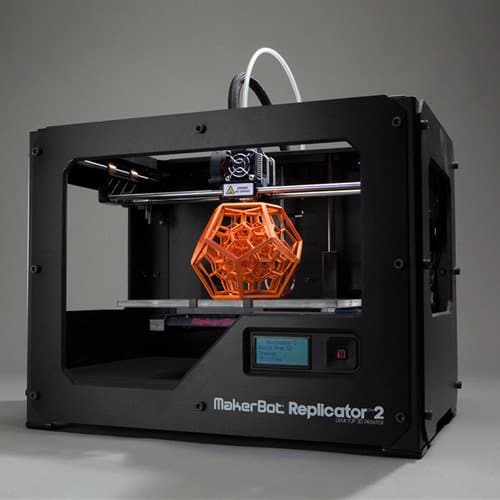

FabLab Leuven is "open source hardware" for students and staff of the KU Leuven Association and Imec, in other words: a library of user-friendly machines to make almost anything in wood and plastic.

For students and staff members of the KU Leuven Association and Imec.

attention: RESERVATION POSSIBILITY for personnel: make your reservation here.

Always bring your personal student or staff card from the KU Leuven Association and Imec with you and register with us before using the machines. We allow maximum 25 persons in our largest FabLab room.

Are you personnel, you can still make your reservation here.

Furthermore you show that you respect our FabLab and the other users by always cleaning up your material when you have finished.

You are only allowed to use one machine per project / person (i.e. if you are making invitiations or tokens for scouts, you can only use one laser cutter). This in respect for the people waiting to use the laser cutter as well.

Personnel can still reserve through our tool.

Monday 8:45 - 17:45 Tuesday 8:45 - 17:45 Wednesday 9:00 - 17:45 Thursday 8:45 - 17:45 Friday 8:45 - 17:45 Saturday Closed Sunday Closed

We zijn open.

Next data we're closed or have different opening hours:

21 Jul Closed

29 May - 30 May Closed 9 Jun - 9 Jun Closed 3 Jul - 11 Jul Closed 15 Aug - 29 Aug Closed 8 Sept - 8 Sept Closed 11 Nov - 11 Nov Closed 25 Dec - 1 Jan Closed

Heb je een idee? Wil je het realiseren? Zoek je een plaats waar je een eerste prototype kan maken om eventuele klanten te overtuigen? FabLab-Leuven is die plaats...

News

During the summer period we are open from 9:00-17:30 on Mon, Tue, Thu, Fri and from 9:15-17:30 on Wednesday.

As from 27 September FabLab is open again without reservation system and this for students of KU Leuven (Association). Possible existing reservations after 27 September will be deleted.

For KU Leuven, Flanders Make and Imec personnel it will still be possible – to a limited extent – to make a reservation for the laser cutter (i.e. on availability basis and reservation needs to be done at least 12 hours on beforehand). Also, please come on time, as we only keep your reservation for max 15 minutes after the start.

Please, note that maximum 25 persons will be allowed to be in the FabLab main room at the same time. Besides that a face mask is always required, also when you are working at the laser cutter.